Extensometers measure the amount of strain a specimen exhibits during a materials test. They are typically used when testing in tension, but can also be used when testing in compression and flexure. Measuring directly at the specimen eliminates any other sources of compliance or deflection in the load string and load cell in order to provide the most accurate measurement possible.

When determining the best extensometer for your application, the most basic information needed is the gauge length and total elongation of your specimens, but there are also other, less obvious factors to consider.

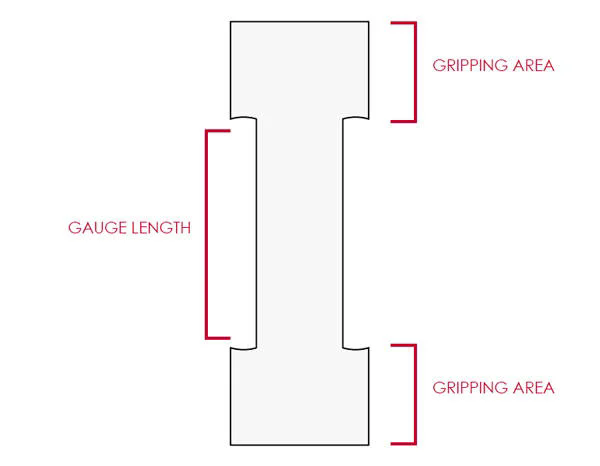

The “gauge length” (GL) is defined in ASTM E6-15e4 Standard Terminology Relating to Methods of Mechanical Testing as ”the original length of that portion of the specimen over which strain or change of length is determined.” For the familiar dog bone specimen, the gauge length will be within the reduced parallel section. The size of the gauge length will typically be defined or suggested by the test standard.

“Strain” is defined as “the per unit change in the size or shape of a body referred to its original size or shape.” “Elongation” is more specifically the change in gauge length due to tensile force, expressed as a percentage. If the gauge length starts at 1 inch and elongation is 100%, then the length of the specimen in the gauge length has increased by 1 inch.

Dog Bone Specimen

The type of material and any test standard requirements will help focus your search for the right extensometer. The “class” or required measurement accuracy is typically stated in the test standard and will be different for materials that exhibit different stiffness (i.e. elastomers vs. composites or ceramics), expected elongation (10%, 50%, 200%, or greater than 1000%), or where certain results need to be measured (i.e. before yield vs. at

The type of material and any test standard requirements will help focus your search for the right extensometer. The “class” or required measurement accuracy is typically stated in the test standard and will be different for materials that exhibit different stiffness (i.e. elastomers vs. composites or ceramics), expected elongation (10%, 50%, 200%, or greater than 1000%), or where certain results need to be measured (i.e. before yield vs. at fracture).

The design of many extensometers is driven by testing standards, but some extensometers are very flexible and adaptable to different materials or types of tests, so you may only need one to meet all your needs. But there are many times where a more specialized device is vital to the application (torsion, biaxial, high temperature, cyclic fatigue, etc.) and may only be suitable for specific specimens (due to size, shape, stiffness, etc.).

Other aspects to consider are the skill level or experience of the operators and how much turnover there may be in your lab. Do you need an extensometer that requires training and is dependent on operator skill and technique, or one with more automation capabilities that requires very minimal training? If the device is fully integrated with the test system and software, most operator errors can be prevented.