- Product Details

Equipment Description

This muffle furnace is used to heat, roast, dry, heat treatment for the colleges and universities, mining enterprise laboratory, chemical analysis, physical test, metal, ceramics, small steel parts.

Main Feature

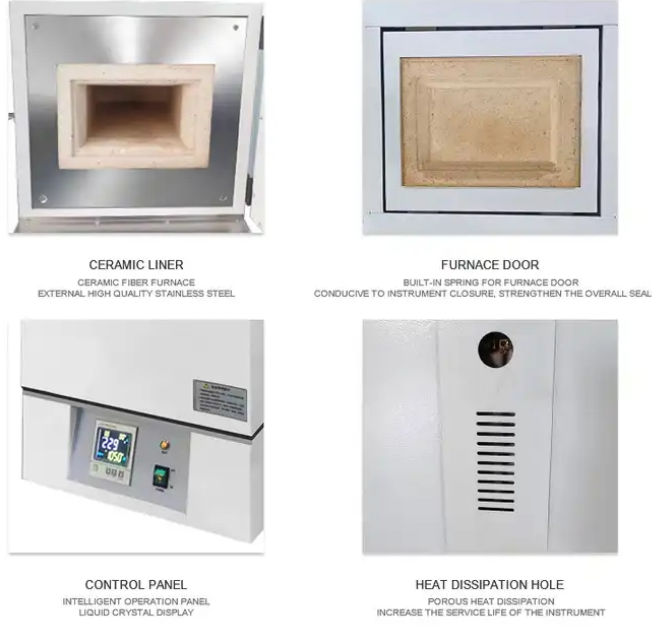

1. All-ceramic fiber furnace structure, light weight, heat capacity of small, low loss air furnace, energy saving over 70%.

2. Heating speed, heating rate can be adjusted. From room temperature to rise to 1000 ℃, generally require 15 to 30 minutes.

3. Programmable to meet the 10 continuous temperature and temperature requirements, automatic heating and temperature, with the PID parameter self-tuning, manual / automatic without interference and over-temperature alarm.

4. Temperature control precision is high, Chong Wen (overshoot) of small, red temperature values of 1-3 ℃. With temperature compensation and temperature correction. Display Accuracy: ± 1 ℃.

5. Good temperature uniformity. SGM2825 Temperature uniformity is ± 2.9 ℃. (General national standard box-type furnace A grade ± 15 ℃, B grade ± 10 ℃, C grade ± 6 ℃.)

6. Integrated structure, a "full door" design, elegant appearance

Technical Parameter

Model Number | HZ-1733-2.5-10L | HZ-1733-4-10L | HZ-1733-8-10L | HZ-1733-2.5-12L | HZ-1733-5-12L | HZ-1733-10-12L |

mode | Four-sided heating | |||||

Maximum service temperature | 1000°C | 1200°C | ||||

Temperature resolution | 1°C | |||||

Temperature fluctuation | ±5%°C | |||||

Time from normal temperature to maximum temperature | 60 | 70 | 75 | 80 | ||

Heating mode | Phased temperature rise | |||||

Exhaust port | Inner Diameter 30mm*1, Rear (optional) | |||||

Furnace body | Aluminum silicate | |||||

heater | Nickel chromium aluminum alloy wire 0Cr27A17Mo2 | |||||

Rated power | 2.5kw | 4kw | 8kw | 2.5kw | 5kw | 10kw |

Outer fitting | Cold rolled steel plate, drug resistant surface coating | |||||

Temperature control mode | Liquid crystal display | |||||

Program mode | matching | |||||

Temperature setting mode | Touch four buttons to set | |||||

Temperature representation | Measuring temperature display :4 digit digital upper display; Setting temperature display :4 digits lower display | |||||

timer | 0-9999 minutes (with timing wait function) | |||||

Running function | Fixed value operation, timing operation, automatic stop | |||||

Additional function | Deviation correction, menu key lock, power failure compensation, power failure memory | |||||

sensor | k-type | |||||

Safety device | Overlift alarm | |||||

Inside dimension (width × depth × height mm) | 120×200×80 | 200×300×120 | 250×400×160 | 120×200×80 | 200×300×120 | 250×400×160 |

Overall dimension (width × depth × height mm) | 410×595×467 | 500×790×527 | 600×910×635 | 410×595×467 | 500×790×640 | 600×910×635 |

Outer package size (width × depth × height mm) | 790×785×550 | 900×900×640 | 930×930×650 | 790×780×550 | 900×900×640 | 930×930×650 |

Internal volume | 2L | 7L | 16L | 2L | 7L | 16L |

Rated current of power supply (50/60 Hz) | AC220V/11A | AC220V/18A | AC220V/12A | AC220V/11A | AC220V/23A | AC380V/12A |

Net weight/gross weight KG | 67/80 | 134/150 | 203/230 | 67/80 | 134/150 | 203/230 |

Additionable configuration | Exhaust port | |||||