- Product Details

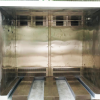

High Temperature Testing Chamber is mainly composed of a box body, heating equipment, air circulation system and control system. The shell is formed by electrostatic spray or fog of cold rolled steel plate surface is made of high quality stainless steel liner, mirror stainless steel plate, the box door is arranged in the middle of a large area of the observation window, and is equipped with an observation lamp, make the user can see the test sample appearance clearly. The overall appearance. The thermal insulation layer is made of rigid polyurethane foam with a small amount of fine glass wool, with high strength, good insulation characteristics. The main temperature of the equipment controller adopts intelligent digital temperature humidity control system, the operation method of humanized design, easy to use, and the function of different grades of instrument operation Compatible with each other. The digital correction system input, built-in thermocouple and thermal resistance of commonly used nonlinear correction table, measuring precision and stability. With the regulating function of the position adjustment and AI artificial intelligence, 0.2 grade precision, a variety of alarm mode. Automatic control and safety protection coordination system. Using stainless steel heating fin heating tube.

Main function

Main features

| Model | HZ-2015-80L | HZ-2015-100L | HZ-2015-150L | |

| Inner chamber size (D×W×H) | 40*50*40 cm | 40*50*50 cm | 50*60*50 cm | |

| Temperature range | Normal temperature~150°C (or customized) | |||

| Fluctuation / uniformity | ≤±0.5°C/.+2°C-3°C | |||

| Control system | Heating system | Fully independent system, nickel chromium alloy electric heater | ||

| Cyclic system | Low temperature and low noise air conditioning motor. Multi blade centrifugal wind wheel | |||

| Materials used | External material | High quality carbon steel plate. Phosphating, electrostatic spray treatment, SUS304 stainless steel noodles, lines, hair processing (optional) | ||

| Internal material | SUS304 Stainless steel mirror plate | |||

| Door insulation | Double layer high and low temperature resistant silicone rubber door seal strip | |||

| Standard layout | Multi layer heating contact with 1 sets of lighting glass window, test rack 2, test lead hole (25, 50mm) 1piece | |||

| Security guard | Leakage, short circuit, over temperature, motor overheating, overload, over-current protection | |||

| Timing function | 0.1~999.9 (S, M, H) adjustable | |||

| Supply power | AC380V±10% 50±0.5Hz, Three-phase Five-wire | |||

| Operation environment temperature request | 5°C~+30°C ≤85%R.H | |||

| Note: 1. The above data are measured at ambient temperature (QT) 25 OC. The chamber has no load 2. Can be customized according to the specific requirements of users of non-standard high and low temperature, low temperature test room | ||||

1. GB 10592-89 Technical specification for high and low temperature test chamber

2. GB 11158-89 Technical specification for high temperature test chamber

3. GB/T5170.2-1996 Test methods for basic parameters of environmental testing equipment for electrical and electronic products

4. GB2423.2-89 Basic test procedure for electrical and electronic products -- Test B: -- high temperature test method

5. GB2424.1-89 Basic environmental test procedures for electrical and electronic products