- Product Details

Product use:

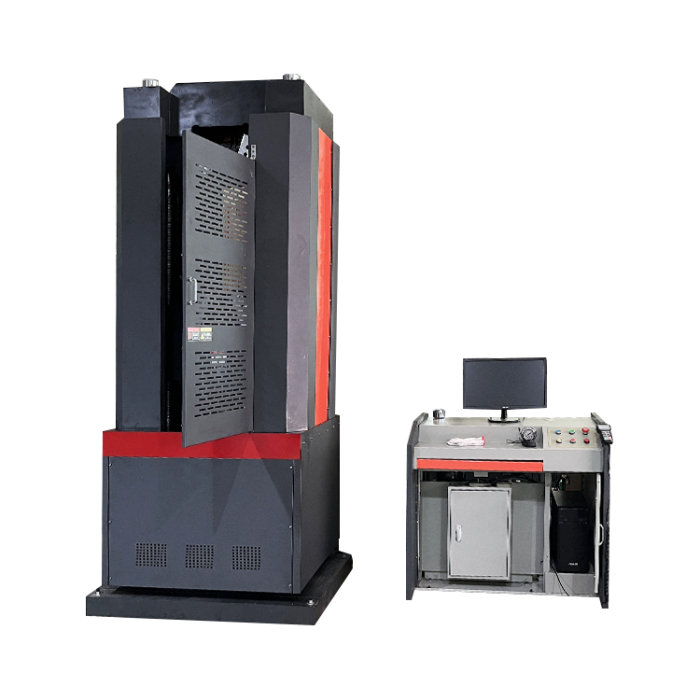

HZ-002 microcomputer electro-hydraulic servo universal material testing machine is a highly versatile product that can meet the various standard tests in the national regulations on metal tensile tests, and can also implement tensile, compression, bending, shear and other types of tests on different materials or products according to other standards. It can obtain the tensile strength, yield strength, specified non-proportional extension strength, elastic modulus and other performance indicators of the measured material, and can achieve closed-loop control such as constant rate loading, constant rate deformation, constant rate displacement, constant rate strain, etc., and can perform process qualification performance verification tests for materials or products.

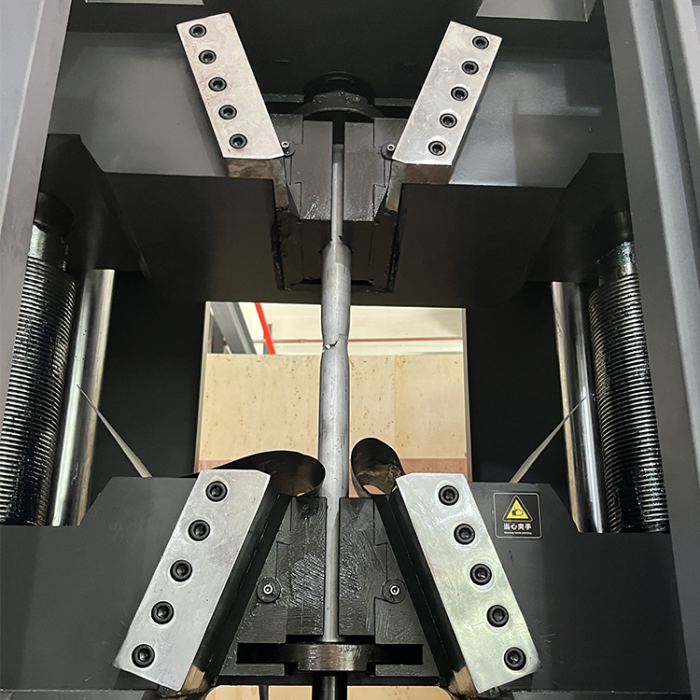

The testing machine has a six-column, double-space structure. The space between the upper beam and the lower beam is the tensile space, and the space between the lower beam and the test bench is the compression space. The test space is automatically adjusted by the rotation of the sprocket and the lead screw to drive the lower beam up and down. The upper and lower beams are equipped with hydraulically controlled clamping jaws. The standard model is equipped with V-shaped and flat jaws for clamping cylindrical specimens and flat specimens for tensile tests; the lower end of the lower beam of the standard model is equipped with an upper pressure plate, and the test bench is equipped with a lower pressure plate with a spherical structure, which can be used for direct compression tests.

The design of the main machine of this testing machine takes into account the possibility of expanding the assembly of other fixtures to complete more tests. For example: equipped with a bolt fixture, it can be used for bolt tension and load retention, equipped with a bending fixture, it can be used for round bar or plate bending tests, equipped with a shear fixture, it can be used for round bar shear strength tests, and in the compression space, flexure, shear, splitting, elastic modulus instruments can be added to the compression space to test concrete and cement specimens. In addition, equipped with steel balls, anchor chains, fasteners and other fixtures, various tests of this product can be completed.

Compliance with standards:

The testing machine and its accessories meet the requirements of GB/T228, GB/T2611, and GB/T16826 standards.

Technical parameters:

| Maximum test force | 2000KN |

| Range | 10-100% (full range without grading) |

| Grade | Level 1 |

| Minimum resolution | 0.01KN |

| Maximum stretching/compression space | Tension ≤800mm Compression ≤650mm |

| Flat clamping thickness | 0-50mm |

| Circular clamping size | 20-70mm |

| Cylinder diameter | 300mm |

| Working piston stroke | 250mm |

| Upper and lower platen dimensions | Φ250mm |

| Maximum lifting speed of tabletop | ≤70mm/min |

| Maximum lifting speed of the moving beam | ≤300mm/min |

| Input power | 380V±10V |

| Motor power | 3KW |

| Host size | 1200*1050*2923mm |

| Control cabinet size | Horizontal cabinet 1100*630*940mm/vertical cabinet 750*560*1540mm |

| Host weight | 6800KG |