- Product Details

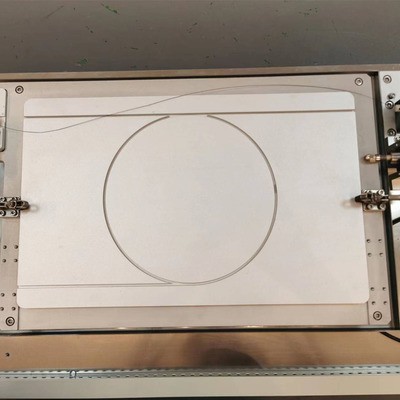

The tension and torque testing machine is a new type of material testing machine that combines electronic technology with mechanical transmission. It has a wide and accurate loading speed and force measurement range, and has high accuracy and sensitivity in measuring and controlling load, displacement, and torque. It can also perform automatic control tests of constant speed loading and constant speed displacement. It is simple and convenient to operate, and is especially suitable for use as a testing instrument for quality inspection bureaus. This series of machines is mainly suitable for testing non-metallic and metallic materials with a test load of less than 10kN and a torque within 100100 N·M.

Main functions:

Mainly suitable for testing metal and non-metal materials, such as rubber, plastic, wire and cable, optical fiber cable, safety belt, safety belt, leather belt composite material, plastic profile, waterproof coil, steel pipe, copper, profile, spring steel, bearing steel, stainless steel (and other high hardness steel), casting, steel plate, steel strip, non-ferrous metal wire, and various tests such as stretching, compression, bending, shearing, peeling, tearing, two-point extension (extensometer is required) and torque of some rotating parts under high temperature environment.

Meet the standard:

"GB/T16491-1996 Electronic Universal Testing Machine"

Application industry:

Widely used in metrological quality inspection; clothing and footwear; rubber and plastic; metallurgy and steel; machinery manufacturing; electronic appliances; automobile production; textile and chemical fiber; wire and cable; packaging materials and food; instrumentation; medical equipment; civil nuclear energy; civil aviation; colleges and universities; scientific research laboratories; commodity inspection and arbitration, technical supervision departments; building materials and ceramics; petrochemical industry; other industries.

Technical parameters:

| Model | HZ-1018 |

| Maximum load | 100N, 200N, 500N, 1KN, 2KN, 5KN, optional |

| Torque range | 0-100 N·M |

| Accuracy level | 0.5 level |

| Effective force measurement range | 0.2%~100% (0.5 grade) |

| Force measurement accuracy | Within ±0.5% of the indicated value |

| Test machine resolution | Maximum load 1/200000, no internal and external division, and full-range resolution unchanged |

| Load sensor | Basic configuration: one tension and compression sensor (maximum load), one static torque sensor Extended configuration: multiple sensors can be added |

| Deformation measurement system (optional according to requirements) | Extended configuration: Small deformation: gauge length 25mm, 50mm, 100mm Deformation range: 5mm, 10mm, 25mm |

| Effective test width | 390mm (can be widened according to customer requirements) |

| Effective stretching space | 400, 500, 600mm (can be increased according to customer requirements) |

| Test speed range | 0.001~500mm/min |

| Displacement measurement accuracy | Within ±0.5% of indicated value / Within ±0.2% of indicated value |