- Product Details

Main function:

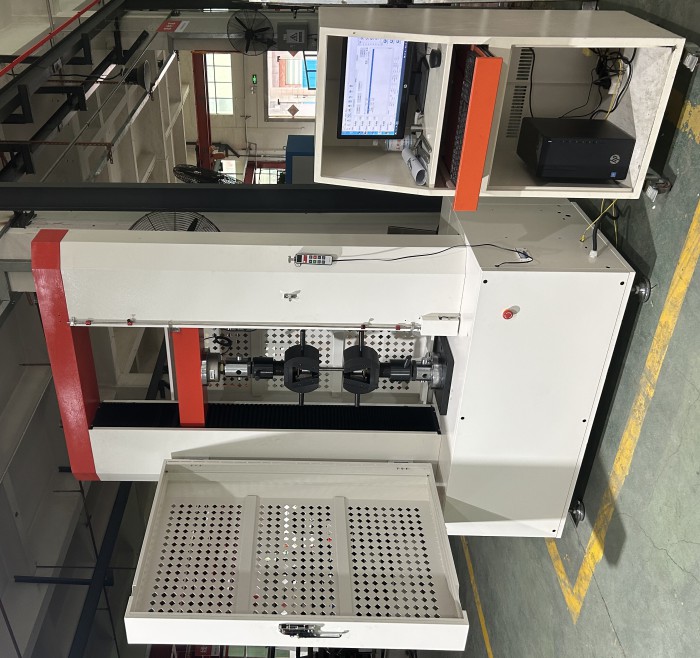

Universal Testing Equipment HZ-1009B mainly applied to test the metallic and non-metallic materials in tension, compression, bending, shear, peel, tear or two-points extensions and others, such as rubber, plastic, wire and cable, optical fiber and cable, safe belt, leather belt composite materials, plastic profiles, waterproof membrane, steel, copper, profiles, spring steel, bearing steel, stainless steel (as well as other high-hardness steel), castings, plate, strip, non-ferrous metal wire.

Main feature:

Adopted photoelectric encoder to measure the displacement, the controller uses the embedded single-chip microcomputer structure with multi-function software, which combined with measurement, control, calculation and storage. It can automatic calculate the stress, rate of elongation (need to add with extensometers), tensile strength, elastic modulus, automated statistical results; automatically recorded the biggest point, breaking point, the designated point value or the rate of elongation; Using computer to display the dynamic curves in the testing process and process the data, After testing, it can re-analysis and editing the data by amplifying the curves through the graphics processing module, printing reports, product performance reached the international advanced level.

Corresponding standard:

GB/T 1040, GB/T 528, GB/T 529, GB/T 8808, GB/T 13022, GB/T 2790, GB/T 3923, GB/T 20310, GB/T 3690, GB/T 4944, GB/T 3686, GB/T 10654, ASTM D882, ASTM D638, ISO 527, ASTM D412, ASTM D3574, ASTM E8, ASTM D412

Technical parameter:

Universal Testing Equipment HZ-1009B mainly applied to test the metallic and non-metallic materials in tension, compression, bending, shear, peel, tear or two-points extensions and others, such as rubber, plastic, wire and cable, optical fiber and cable, safe belt, leather belt composite materials, plastic profiles, waterproof membrane, steel, copper, profiles, spring steel, bearing steel, stainless steel (as well as other high-hardness steel), castings, plate, strip, non-ferrous metal wire.

Main feature:

Adopted photoelectric encoder to measure the displacement, the controller uses the embedded single-chip microcomputer structure with multi-function software, which combined with measurement, control, calculation and storage. It can automatic calculate the stress, rate of elongation (need to add with extensometers), tensile strength, elastic modulus, automated statistical results; automatically recorded the biggest point, breaking point, the designated point value or the rate of elongation; Using computer to display the dynamic curves in the testing process and process the data, After testing, it can re-analysis and editing the data by amplifying the curves through the graphics processing module, printing reports, product performance reached the international advanced level.

Corresponding standard:

GB/T 1040, GB/T 528, GB/T 529, GB/T 8808, GB/T 13022, GB/T 2790, GB/T 3923, GB/T 20310, GB/T 3690, GB/T 4944, GB/T 3686, GB/T 10654, ASTM D882, ASTM D638, ISO 527, ASTM D412, ASTM D3574, ASTM E8, ASTM D412

Technical parameter:

| Model | HZ-1009B |

| Maximum load | 1ton, 2ton, 5ton, 10ton, option |

| Accurate grade | 1grade / 0.5 grade |

| Effective measuring range | 0.2%~100% (1 grade) / 0.4%~100% (0.5 grade) |

| Measuring accuracy | the value ±1% / the value ±0.5% |

| Tester resolution | Max load 1/200000, constant the resolution |

| Load sensor | Basic configuration: sensor (max load): one |

| Extended configuration: can add more sensors | |

| Effective testing width | 400mm (can be customized ) |

| Effective tensile stroke | 1000mm; 1200mm; 1400mm (can be customized) |

| Range of testing speed | 0.001~500mm/min |

| Accuracy of displacement measurement | Tolerance: ±0.5% / tolerance: ±0.2% |

| Deformation of measured system (according to the requirements) | Min span: 10mm, Max range of deformation: 800mm Extended deformation: Min span: 25mm, 50mm, 100mm, range of deformation: 5mm, 10mm, 25mm |

| Accuracy of measured deformation | Tolerance: ±0.5% |

| Safety | Electronic-limit protection |

| Testing platform moving device | Fast /slow two speeds to control, can jog |

| Back to function of testing platform | Manual or automatic operation, After the test, the moving iron return to initial position with the highest speed by manual or automatic operation |

| Overload protection | Overload 10%, automatic protection |

| Fixture | According to customer's need |

| Machine size | 107*56*210cm (length*width*height) |

| Motor | Panasonic AC servo motor and drive |

| Power supply | 220V, 50HZ |

| Power | 0.75KW (depending on different demand of force, using different motor) |

| Weight | (about) 320 Kg |

| Unit | Kg, N, LB, TON can be exchanged |